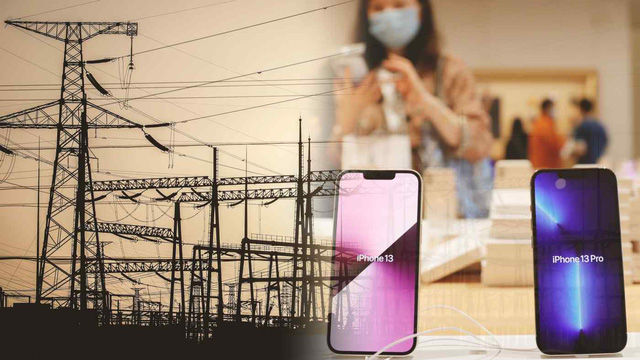

The electricity crisis in China has a direct impact on the global supply chain, which is burdensome to the struggling world economy to fight against the pandemic.

The electricity crisis is having a far-reaching impact on China’s entire manufacturing and supply industry

China is facing the biggest electricity crisis that has not been seen in more than a decade. Part of the reason is because Beijing’s policies include efforts to limit carbon emissions. This situation has had a significant impact on the global economy, which has been reshaped by the pandemic.

China’s industrial giants have been grappling with soaring electricity prices and have had to restrict their use of electricity since at least March. At that time, the Inner Mongolian government ordered some heavy industries such as aluminum smelters, to limit their electricity use and reach the first-quarter energy goals.

By May, manufacturers in Guangdong, China’s main exporting province, received similar requests amid hot weather combined with lower-than-normal hydropower output, straining the national grid system. Other large industrial zones along the country’s east coast are also subject to power consumption restrictions and rotating power cuts.

By September, the restriction on electricity use had spread to 16 provinces and cities, i.e. more than half of China, including the capital Beijing, and affected both household and domestic electricity such as electricity used in public places.

Electricity crisis creates a new wave of shifting supply chains away from China

Suppliers of Apple, Amazon and many other large corporations are gradually moving their production out of China to avoid the risk of “over-concentration of production” in the mainland.

After a week of severe power shortages in late September, many of Apple’s suppliers have warned that power cuts pose a major threat to the supply chain. Worries about manufacturing disruption will become a long-term trend. “We know that this situation could last until the end of the year or so,” said an executive at a speaker manufacturer in Dongguan, Guangdong province.

This is a company that specializes in providing products for Amazon, Lenovo and many other brands. But the company only operates 3 days a week due to limited power supply. “Such inconveniences will gradually become more than we can bear. Now we once again have to re-evaluate our plan to open new facilities outside of China, maybe in Vietnam, Indonesia or Thailand,” the executive shared.

Vietnam’s supply chain “benefits” from China’s electricity crisis

Statistics show that the output and selling price of steel – cement Vietnam exported to China recorded a strong growth in August and September compared to the previous period from May to July; at the same time construction material exporters in China were asked to cut their capacity due to lack of electricity. Vietnamese building material exporters are benefiting from a temporary supply shortage in the neighboring country.

Mr. Nguyen Thien Ngon – General Director of A Dong Co., Ltd, one of the leading shelf manufacturers in Vietnam, said: “During this period of time, retail brands looking to A Dong increased dramatically to compensate for the counter supply shortage from Chinese manufacturers. This is a great opportunity for Vietnamese suppliers to demonstrate their production capacity and home-field advantages such as quality, progress and long-term cost problems.”

“Vietnam is one of the countries benefiting the most from the ongoing shift and diversification of supply chains.Vietnam’s advantages include relatively low production costs compared to China, a skilled and well-trained workforce, and good infrastructure thanks to huge investments over the past decade”, said Rajiv Biswas, an economic analyst at IHS Markit, a leading global company providing analysis of major industries and markets.

Facing the increasingly strong movement of big brands, Vietnamese manufacturing enterprises are also rapidly consolidating their capacity to take over and enlarge their role in the supply chains.

The companies actively invest in technology to produce, operate and perfect logistics networks at increasingly competitive costs. Enterprise’s responsiveness and flexibility to market changes is a vital factor in determining whether a business can seize opportunities from this big movement or not.

Nguồn: https://cafef.vn/chuoi-cung-ung-viet-nam-huong-loi-tu-khung-hoang-dien-trung-quoc-20211120143129338.chn