Precision Metal Cutting for OEM Display Shelving Production

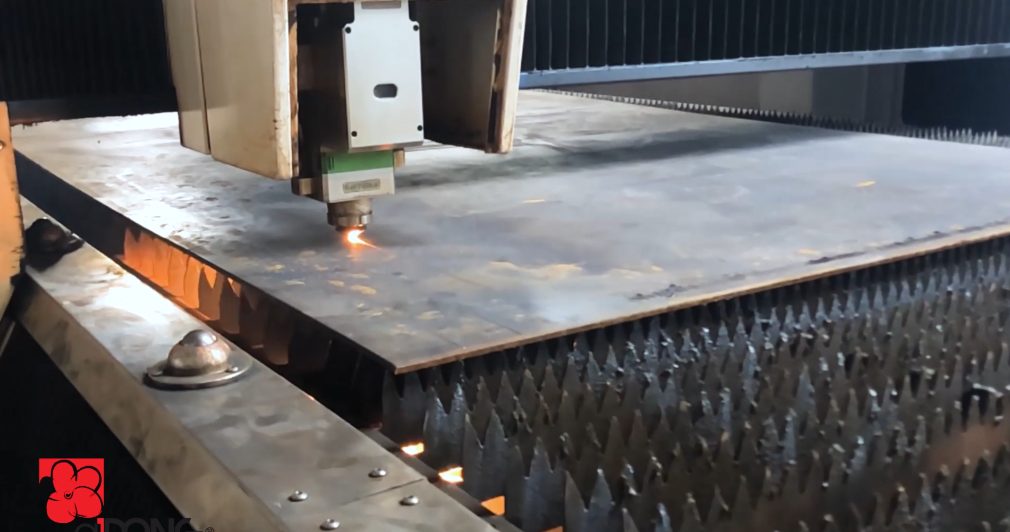

In the manufacturing of supermarket shelving, retail display racks, and POSM systems, precision is a fundamental requirement. At ADONG Factory, laser cutting is not a standalone service—it is a core production stage integrated into our end-to-end OEM display shelving manufacturing process.

As a professional OEM display shelving manufacturer in Vietnam, ADONG Factory invests in laser cutting technology to ensure accuracy, structural stability, and consistent quality from the very first step of production.

Laser Cutting: The First Step in Display Shelving Manufacturing

At ADONG Factory, every display shelving project begins with approved technical drawings and specifications. Based on these drawings, metal components are processed through our in-house laser cutting system.

Accurate laser cutting at this initial stage allows us to:

Achieve exact dimensions according to OEM drawings

Maintain uniformity across all components in the same production batch

Create a solid foundation for subsequent processes such as bending, welding, and assembly

For large-volume OEM orders, precision at the cutting stage directly determines the consistency of the final shelving system.

How Laser Cutting Affects Shelf Structure and Load Capacity

Display shelving must meet not only aesthetic requirements but also structural strength, safety, and load-bearing standards for retail environments.

By applying laser cutting technology, ADONG Factory ensures that metal components:

Fit precisely during assembly

Maintain alignment during structural welding

Support stable and durable shelving structures

This precision contributes directly to the long-term durability and safety performance of supermarket and retail shelving systems.

Integrated with a Complete Manufacturing Process

Laser cutting at ADONG Factory operates as part of a fully integrated manufacturing workflow, including:

Laser cutting → Bending → Welding → Surface treatment → Powder coating → Assembly → Quality inspection

This closed-loop production model allows ADONG Factory to control quality at every stage, prevent cumulative errors, and deliver consistent OEM results.

Enhancing Surface Quality for Powder Coating

High-quality laser cutting produces clean edges and smooth metal surfaces, which are essential for the next finishing stages.

Well-cut components help to:

Improve powder coating adhesion

Ensure uniform coating thickness and color

Enhance the overall visual quality of finished shelving

This is especially critical for retail display shelving and export products, where appearance plays a key role in brand image.

Quality Control at the Laser Cutting Stage

At ADONG Factory, quality control starts from laser cutting. Each cut component is checked for:

Dimensional accuracy

Shape consistency

Compliance with technical drawings

By identifying deviations early, we minimize production risks and maintain stable quality throughout the manufacturing process.

ADONG Factory is your trusted partner for OEM display shelving production in Vietnam, offering precision manufacturing, controlled processes, and export-ready quality.

👉 Contact ADONG Factory to discuss your OEM shelving requirements.